How much resolution is really needed? Part 1

1080p, 720i, Megapixel, 2 Megapixels, 4, 8, 24 Megapixels… 4K, 8K, or even Gigapixels, yes, that’s a thing! But what does this all mean in terms of a...

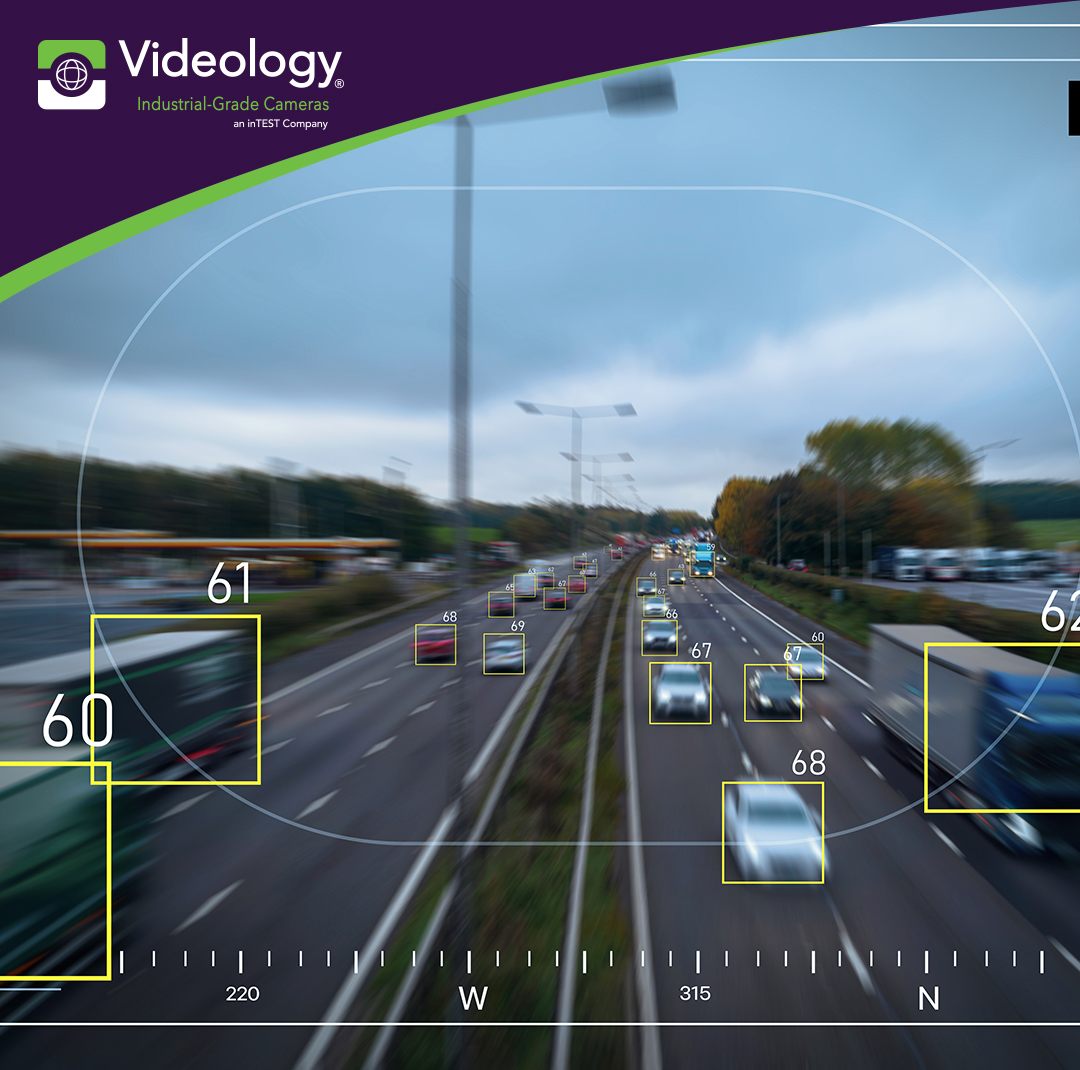

SCAiLX AI Imaging

SOFTWARE

Excellence. Every day. Every time.

MARKETS SERVED

Excellence. Every day. Every time.

ONLINE TOOLS

DOCUMENTATION

Excellence. Every day. Every time.

OUR COMPANY

OUR PRESENCE

OUR PARTNERS

Excellence. Every day. Every time.

3 min read

Brian Fletcher

May 8, 2024

Brian Fletcher

May 8, 2024

In the Part 1 blog "How much resolution is really needed?" we discussed what resolution means in terms of practical industrial application and looked at different types of resolutions and the compromises associated with each. In this second part of the blog series, we will uncover other important factors in determining how much resolution is needed for your project.

The variance of the random distribution of light photons recorded on a sensor is defined as Shot Noise. As pixel size varies, the amount of photons registered at a single location in a given amount of time will vary. Larger pixels will register a more consistent number of photons for a given amount of light based on probability. As the pixel size decreases, the statistical probability of recording a consistent number of photons decreases and thus increases the Shot Noise of the resulting image.

What does this have to do with resolution? As the demand for higher and higher resolution continues to rise and the need to reduce the overall size of the camera continues, the pixel size must be reduced to increase the pixel density or the sensor size must get larger.

Which direction to choose? This depends on the application. Do you have all the light in the world? Is noise not a big concern? Then maybe a high-resolution sensor with smaller pixels would be a great fit. If not, then consider if the project really requires the spatial resolution in the first place, and look for a sensor with a larger pixel. Or for the best of both worlds, provided cost not being a factor, go for a larger sensor altogether.

It is important to keep an eye on costs with respect to resolution. Sensor size and complexity directly impact the overall cost of the sensor. There are three main drivers of cost at play.

First, the sensor design is a complex process and as the sensors increase in density the complexity also increases, driving up cost.

Second, the sensor is manufactured as a silicon chip and as the size of the chip increases, fewer sensors fit per plater.

Third, the fall-out rate increases as the size of the chip increases. Together, these three factors increase the cost of producing larger sensors exponentially. In this case, do not select a sensor based on price, even though cost is almost always a driver. However, down-select the sensors based on performance first. Once the field is narrowed down to sensors that can fulfill the requirements, then look at the cost versus performance of those sensors for the final selection.

Frequency resolution, or frame rate, is the measurement of how many images, or data samples, per unit of time are recorded. Depending on how fast the subject of interest is moving will play a large role in determining the frequency resolution required for a given application.

In some cameras, it is possible to trade spatial resolution for frequency resolution. For example: reducing from 1080p to 720p may increase the frame rate from 30 f/s to 60 f/s. The option to trade-off between spatial resolution and frequency will vary depending on camera models, however, the principal behind the compromise is the amount of data being sent. This bottleneck may occur in the camera, transfer convention, frame grabber, or other parts of the system.

When selecting a camera system for a given project, it is important to know how fast the subject will be moving as well as the acceptable data step between data points. Set your minimum frequency requirement and look at cameras that meet that mark or above.

Lens resolution is a much bigger topic than we have time and space for in this blog post. Look forward to a full blog post dedicated to this topic later in the year. But for now, let’s start with this; there are NO pixels in a lens, and the megapixel lens scale has become obsolete. The megapixel scale can be used loosely as a rule of thumb and should get you close as long as the lens image circle and the sensor format size are closely matched.

The better way to understand the resolution of a lens is to look at the MTF (modulation transfer function) curve. This curve not only takes into account the lens resolution, typically measured in LP/mm (lines pairs per millimeter) but also the contrast the lens is able to achieve. Either way, you look at it there are some trade-offs to be made between cost, performance, and size/weight.

The better way to understand the resolution of a lens is to look at the MTF (modulation transfer function) curve. This curve not only takes into account the lens resolution, typically measured in LP/mm (lines pairs per millimeter) but also the contrast the lens is able to achieve. Either way, you look at it there are some trade-offs to be made between cost, performance, and size/weight.

When choosing the best option for a project start with performance, if a lower-resolution lens is good enough, then use it, it is good enough for the need and it will be cheaper, lighter, and probably smaller than a higher-resolution lens. However, if the project demands a high-resolution lens for the desired results, expect an increase in size/weight as well as cost.

As you can see there is much more to the resolution power of industrial imaging solutions than “just” how many Megapixels the camera has. Videology has 25 years of experience working with our clients to identify the correct compromise between imaging components to satisfy our client’s performance-to-cost ratio. If you have an up-and-coming development where an OEM camera will be required, reach out, we would love the opportunity to bring our experience to your project and demonstrate the value Videology can add.

1080p, 720i, Megapixel, 2 Megapixels, 4, 8, 24 Megapixels… 4K, 8K, or even Gigapixels, yes, that’s a thing! But what does this all mean in terms of a...

Companies dealing with any type of transportation of goods and passengers are under constant pressure to increase agility, speed, and...

The first zoom block cameras were introduced to the market in the early 2000s. They brought a significant transformation to the imaging industry and...

HEADQUARTERS LOCATION

Videology Industrial-Grade Cameras

35 Hampden Road

Mansfield, MA 02048

United States

Directions

+1 401 949 5332

sales@videologyinc.com